third party manufacturing burberry | Burberry business model third party manufacturing burberry The company outsources the manufacturing, but purchases directly, or retains full control over the purchase by third-party manufacturers, of all raw materials that bear the Burberry name.

$25.00

0 · thomas Burberry company

1 · Burberry supply chain renewal

2 · Burberry supply chain

3 · Burberry plc corporate model

4 · Burberry plc

5 · Burberry model pdf

6 · Burberry clothing company

7 · Burberry business model

Sao Paolo, Brazil. Getty Images. More Americans than ever are working remotely — it's led to an uptick in homebuyer migration. While some will relocate within the US, others may consider a move.

Burberry recognises the importance of identifying chemicals which have a potentially negative .Burberry recognises the importance of identifying chemicals which have a potentially negative impact on our environment and this is core to our screening and management processes. We will regularly analyse products in our ranges to identify any deliberate use of listed chemicals and Bringing production back in house presents both opportunities and challenges to Burberry. It gives Burberry more control over manufacturing, marketing and distribution, lowers logistics costs, and reduces the firm’s carbon footprint due to a shorten supply chain.We combine traditional craftsmanship and innovative manufacturing techniques to create desirable products. Our design teams are based in London, where we are headquartered. We weave gabardine and make our Heritage Trench Coats at our mill and factory in Yorkshire, UK.

Burberry has outsourced the quality control management of the Thomas Burberry collection to a third-party specialist. Burberry also grants a limited number of licences to those firms capable of producing “brand-enhancing products”, which require specialist expertise. The company outsources the manufacturing, but purchases directly, or retains full control over the purchase by third-party manufacturers, of all raw materials that bear the Burberry name.We have successfully implemented a traceability pilot for cotton, wool and synthetics with our key suppliers by using a third-party traceability tool that allows us to track these fibres back to the country of origin. Burberry’s team operates each of these manufacturing facilities and follows Burberry’s quality standards. However, on some occasions, Burberry partners with third-party manufacturers and suppliers in the States to produce some of their merchandise.

In a step forward for the UK’s reshoring efforts, knitwear brand John Smedley is opening up its factory in England for third-party manufacturing for the first time in 40 years. Until the mid-1980s, John Smedley created knitwear for luxury players including Prada, Burberry, Paul Smith and Vivienne Westwood.Limited distribution channels: Burberry operates primarily through its retail stores, limiting its exposure to other distribution channels such as third-party retailers.Our leather goods centre of excellence, Burberry Manifattura, has its home in Scandicci, near Florence, Italy. Here, our highly skilled teams produce our product prototypes, explore new engineering innovations and coordinate our leather goods production. Discover manufacturing jobs in Burberry Manifattura hereBurberry recognises the importance of identifying chemicals which have a potentially negative impact on our environment and this is core to our screening and management processes. We will regularly analyse products in our ranges to identify any deliberate use of listed chemicals and

Bringing production back in house presents both opportunities and challenges to Burberry. It gives Burberry more control over manufacturing, marketing and distribution, lowers logistics costs, and reduces the firm’s carbon footprint due to a shorten supply chain.We combine traditional craftsmanship and innovative manufacturing techniques to create desirable products. Our design teams are based in London, where we are headquartered. We weave gabardine and make our Heritage Trench Coats at our mill and factory in Yorkshire, UK.Burberry has outsourced the quality control management of the Thomas Burberry collection to a third-party specialist. Burberry also grants a limited number of licences to those firms capable of producing “brand-enhancing products”, which require specialist expertise.

The company outsources the manufacturing, but purchases directly, or retains full control over the purchase by third-party manufacturers, of all raw materials that bear the Burberry name.

thomas Burberry company

We have successfully implemented a traceability pilot for cotton, wool and synthetics with our key suppliers by using a third-party traceability tool that allows us to track these fibres back to the country of origin. Burberry’s team operates each of these manufacturing facilities and follows Burberry’s quality standards. However, on some occasions, Burberry partners with third-party manufacturers and suppliers in the States to produce some of their merchandise. In a step forward for the UK’s reshoring efforts, knitwear brand John Smedley is opening up its factory in England for third-party manufacturing for the first time in 40 years. Until the mid-1980s, John Smedley created knitwear for luxury players including Prada, Burberry, Paul Smith and Vivienne Westwood.

Limited distribution channels: Burberry operates primarily through its retail stores, limiting its exposure to other distribution channels such as third-party retailers.

Burberry supply chain renewal

Burberry supply chain

Burberry plc corporate model

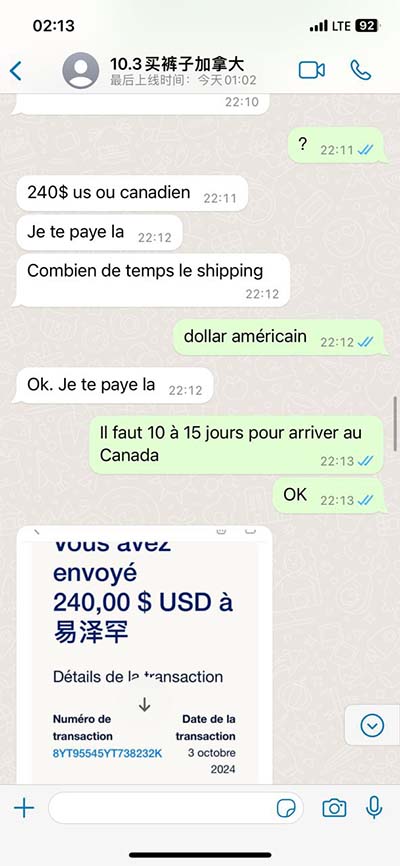

This page is dedicated to jobs and vacancies for AML (Anti Money Laundering) and MLRO (Money Laundering Reporting Officer) skills. There are good career opportunities in .

third party manufacturing burberry|Burberry business model